ISSA EMEA Portal

ISSA Europe, Middle East & Africa (EMEA)

Welcome to ISSA’s portal for the EMEA community! As an ISSA member, you are part of a trusted global community along with more than 10,500 of the industry’s top solutions providers. This page outlines member benefits, events, business tools, and additional resources you can utilize to enhance your business. Connect, learn, and influence with your global cleaning industry association!

Not a member of ISSA? Join today!

Connect

- Member Networking Events: meet like-minded individuals for business relationships

- International Executive Events: ISSA Pulire Forum

- Customised International Expansion Support

- Global Trade Shows: receive special rebates

Learn

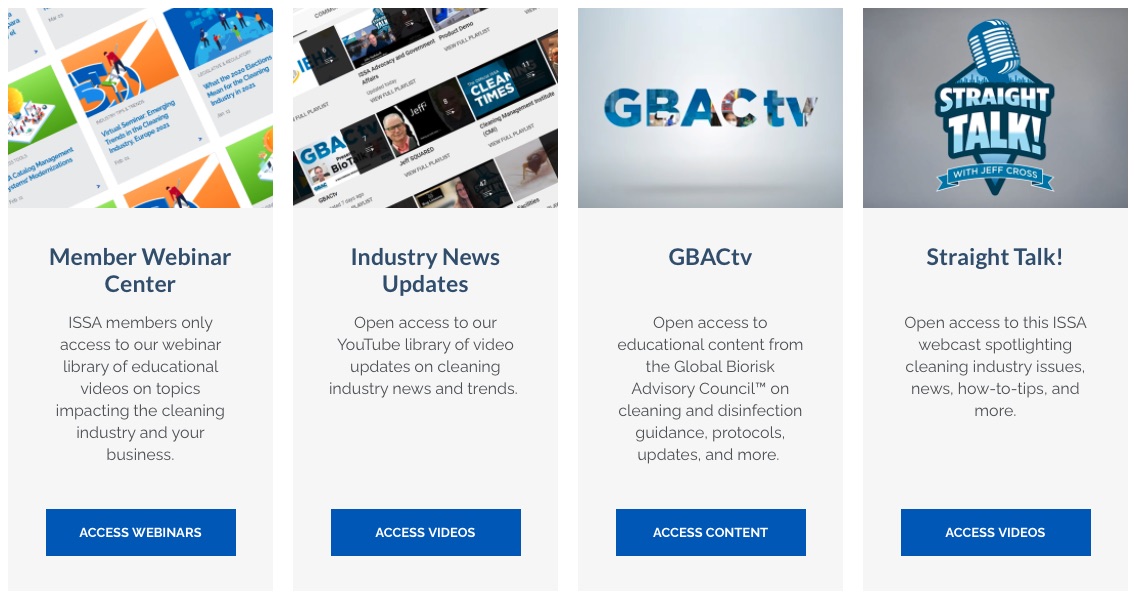

- Quality Education Programmes: highly topical themes, face-to-face interactions with peers, experts and trainers during conferences, seminars, workshops, classes, and webinars

- Valuable Market Data:

- White Paper “Innovation Management in Europe” (download overview, contact us for full white paper)

- White Paper “Impact of the coronavirus crisis on the cleaning industry in West Africa” (2021). (download overview, contact us for full white paper)

- European IOT (Internet of Things) Report

- Market Snapshots

- Industry News: ISSA Today

- Resources for your business:

Featured Success Stories

Influence

- ISSA Focus Groups: contribute to industry white papers and research reports

- Raise your profile: build a solid basis to be able to influence legislation. Use the combined resources of all members of ISSA to talk to lawmakers and sway public opinion

Contact Us

ISSA’s helpful EMEA staff provides regional support and can help you connect with a growing network of local peers. Contact us to learn more.

Phone: (+39) 02 674 4581

Via Felice Casati, 32

20124 Milan (MI)

Italy