ATP Testing vs Visual Inspection: How to Know a Surface is Clean

At the heart of safety is prevention. All facilities need to implement a robust program to identify and correct potential safety issues. As part of the preventative approach, businesses and healthcare facilities have used additional monitoring methods to determine the overall hygiene of employee areas and hospital rooms. They must maintain strict cleaning and sanitation processes. This is where the role of the janitorial/sanitation professional is essential. If a surface hasn’t been adequately cleaned and sanitized, the risk of contamination increases dramatically, potentially decreasing the business’s ROI and bottom line and impacting patient/staff safety.

Business organizations face challenges that are not often addressed. They must clean and disinfect to maximize employee safety and to reduce the risk of transmission of viruses and other pathogens. Recently, the COVID-19 pandemic has raised public awareness of the need to control the spread of infectious diseases, making it even more critical that sanitation professionals monitor the effectiveness of cleaning and disinfection procedures. As a result, routine monitoring has expanded and now impacts any high touch point surfaces in public places, such as airports, hotels, schools, and state, city, and county offices. These public places need verified and validated methods to ensure areas are clean and sanitized to remove the risk of infection transfer.

Importance of Cleaning

For cleaning and sanitizing to work, it must be performed properly and sequentially. Though we might have thought otherwise, disinfectants are not designed to remove organic material, whether bacterial, viral or other debris. Therefore, it is critical to not only clean first but also to disinfect and test areas to confirm they are free of contaminants.

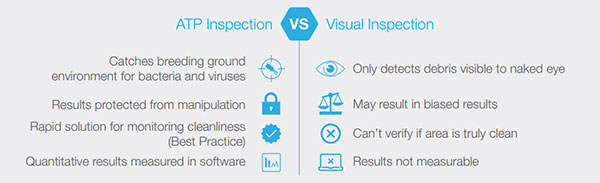

Businesses and healthcare facilities have traditionally performed either visual inspections (relying on the naked eye) or microbial tests (swabbing surfaces and testing for growth in a lab) to help evaluate whether environments are safe and free of any potential pathogens. While inexpensive and fast, visual inspections are imprecise, subjective, and may be unacceptable in many facilities, especially healthcare.

On the other hand, in the past, the only way to know how well a surface was cleaned, was to take a sample and send it for microbial contamination, which was time-consuming, taking days to get results. Without the information, there was no way to immediately know how well the area was cleaned. Recently, in the wake of COVID-19, facilities, especially large businesses, have turned to new technologies that can provide rapid, objective, and reliable measures of cleanliness. Many have turned to a rapid, reliable, easy-to-use solution, adenosine triphosphate (ATP) monitoring (ATP testing).

What is ATP Testing?

Unlike other methods, ATP testing provides results in seconds and is sensitive, quantitative, effective, and straightforward. Microbes and organic materials contain ATP, an indicator of biological residues that can be easily detected to measure cleanliness because effective cleaning and sanitation remove all ATP from the contact surfaces (or production lines in the case of food processors). A failed ATP test indicates that the surface does not meet cleaning standards and should be recleaned.

Since ATP is an indicator molecule for the presence of biological residues, ATP levels can be used to monitor cleaning effectiveness. To measure ATP, a sample is collected from a surface or water via a swab and placed in a reading device, a luminometer. ATP monitors deliver data using bioluminescence, read as a Relative Light Unit (RLU). The higher the RLU, the greater the risk of potential contamination. ATP monitoring doesn’t directly identify bacteria or viruses. Instead, it detects the general presence of organic matter, which bacteria and viruses can use to grow or spread. ATP systems, therefore, can effectively verify the cleaning processes.

Implementing Testing

Other industries have adopted this process, such as hospitality, schools, and healthcare. Since these facilities need to maximize the safety of their employees and visitors through proper cleaning and monitoring of its effectiveness, ATP testing is ideal. Other businesses have also adopted this methodology, bringing in specialists to audit facilities for cleanliness.

No matter what business you’re in, in times like these, it is imperative that rapid, accurate and simple methods must be used to ensure surfaces have been adequately cleaned. It is essential to implement measures that can provide numerical data to support your cleanliness claims to reassure the public and positively impact health and safety. This means incorporating testing above and beyond visual inspection.

An Excellent Solution

Hygiena’s cleaning verification solutions can tell you in as little as 10 seconds if a surface has been cleaned properly. ATP testing detects the presence of biological material which promotes the growth of microbes, such as bacteria and yeast, and gives an objective indication of whether cleaning standards have been met.

Our most advanced ATP monitoring system, EnSURE® Touch, measures ATP levels and provides rapid and accurate sanitation verification data. Our ATP testing devices, including UltraSnap® and AquaSnap®, are explicitly designed for the system. The test devices are user-friendly, designed to maximize sample collection and recovery. After swabbing a surface or collecting a food or water sample, the system rapidly measures ATP levels from the device, providing a numerical value indicating the level of cleanliness. UltraSnap devices are the easy-to-use, superior option for accurate, repeatable testing, meaning you can be confident in the data gathered and the cleanliness of each location.

Similar to a smartphone and using wireless technology, EnSURE Touch syncs and stores all data in our cloud-based software, SureTrend® Cloud. This allows you to monitor, track, and trend testing results across multiple locations/instruments, and schedule reports, making risk management easier than ever. Move beyond visual inspection and traditional microbial testing with quantifiable test results from ATP monitoring using Hygiena solutions. Learn how you can help create a safer, healthier planet by moving past visual inspection at www.hygiena.com.