International Cleaning Week

Spotless Spaces Competition Finalist

Toyota Manufacturing Plant

Verde Clean, BSC

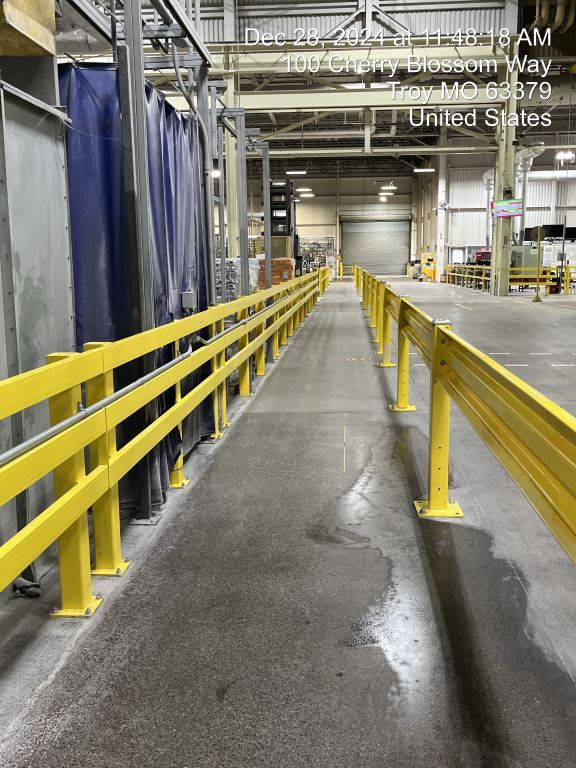

The Toyota Manufacturing Plant in Troy, Missouri, is a state-of-the-art facility that reflects the company’s commitment to quality, innovation, and sustainability. As one of Toyota’s key production sites in North America, the Missouri plant focuses on producing high-quality vehicles while incorporating advanced manufacturing techniques and lean production principles.

What specific measures do you or your team implement to ensure this space meets the highest standards of cleanliness and embodies the value of clean?

The Verde team at Toyota Missouri is dedicated to maintaining the cleanliness of the expansive 550,000-square-foot facility, ensuring a safe and welcoming environment for all employees and visitors through our industry-leading green cleaning and customer service philosophy. With sustainability at the core of our mission, vision, and values, we use eco-friendly cleaning products and processes that effectively address dirt and grime, improve indoor air quality, and reduce environmental impact.

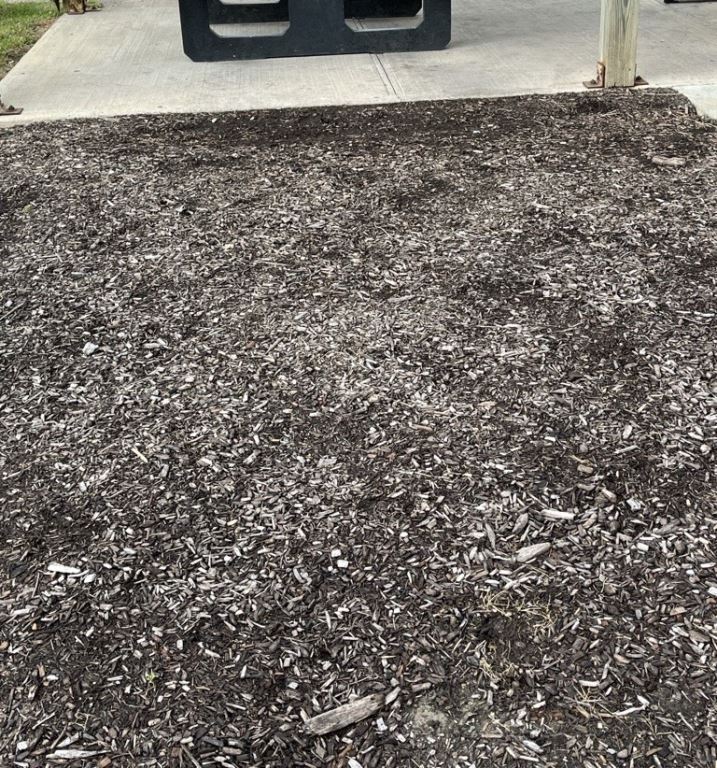

Our team works diligently to keep all areas—including manufacturing floors, the café, restrooms, walkways, and the building’s exterior—spotless and hygienic. With a rigorous cleaning schedule, our janitorial staff operates 24 hours a day to uphold the highest standards of cleanliness, reflecting our commitment to excellence and the well-being of everyone in the facility.

How does cleaning this space contribute to the health and safety of those who use it?

The Verde Vibes Crew’s hard work not only enhances the overall appearance of Toyota’s plant but also contributes to a productive, equitable, and healthy workspace for everyone. As a company, Verde’s commitment to green cleaning and sustainability ensures a safe, healthy facility for industrial workers while creating an inclusive and welcoming experience for visitors, including executives from Japan and around the world.

The cleanliness and appearance of a space shape our perception of the company that owns it, as well as the products and services they provide. When guests arrive at the plant, they often expect a manufacturing facility to be dirty. Instead, they are impressed by the cleanliness and attention to detail throughout the facility. This positive first impression reflects our high standards and Toyota’s commitment to excellence in every aspect of their operation. By maintaining such a pristine environment, we demonstrate that safety, sustainability, and quality are at the core of our values—an impression that extends to both Verde’s and Toyota’s brands and cultures.

What does having a spotless space mean to you and your team?

For my team and me, keeping the Toyota Manufacturing Plant spotless means much more than just a job well done. It represents our commitment to the health and safety of both Verde and Toyota’s teams and to teamwork itself. A clean, organized environment fosters pride and responsibility, allowing everyone to focus on their tasks with clarity and efficiency. It reflects our respect for colleagues and visitors alike.

A spotless space not only boosts productivity on Toyota’s busy manufacturing line but also creates a positive atmosphere where creativity and collaboration can thrive—values that Toyota deeply cherishes. By maintaining this pristine environment, we janitorial workers contribute to the strength of American auto manufacturing and Japanese technological ingenuity, all here in Missouri.

Together, we take ownership of our surroundings, knowing that our efforts contribute to a safe, welcoming, and professional environment that reflects both Verde’s and Toyota’s Kaizen principles. All of which is to say: Cleaning buildings is a lot bigger than just cleaning buildings!